Transporting sea otters over long distances is stressful. For otters that have been exposed to oil, this stress can cause death or seriously complicate medical conditions. Mobile triage units are beneficial in certain cases because they allow staff to stabilize the animals medically before they are flown long distances to a regional rehabilitation center. Mortality can be reduced significantly if mobile units are employed when large numbers of otters must be captured more than 500 miles (five-hour helicopter flight) from the regional center.

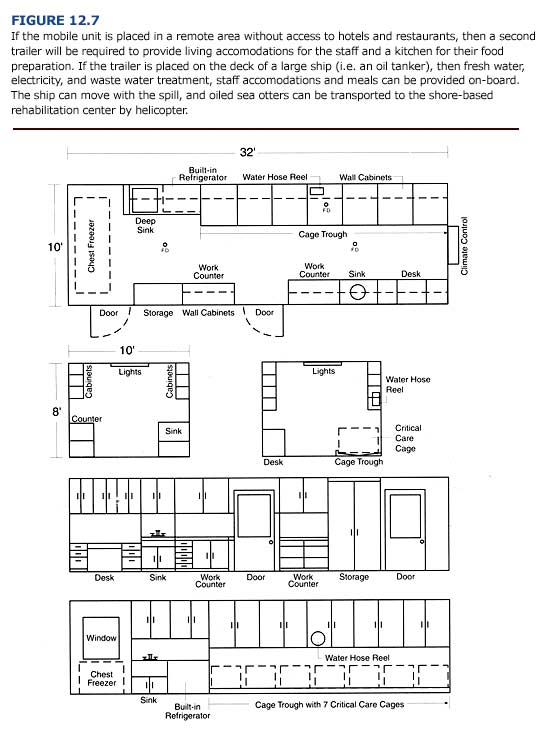

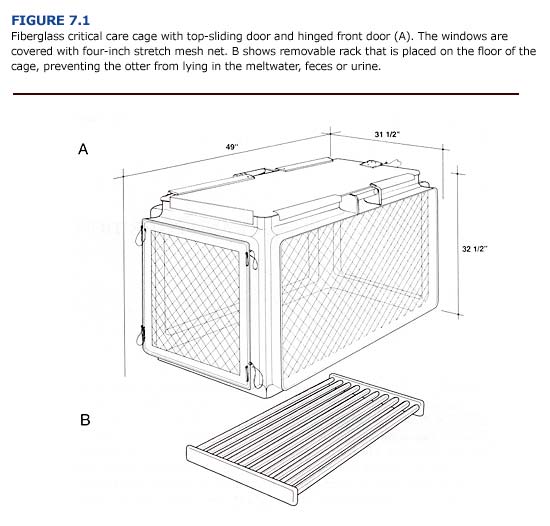

These mobile units, by necessity, are self-contained (including electrical generators and hot water) and transportable by truck, ship, large helicopters, or fixed-wing aircraft (C-130 cargo plane); the latter may be necessary for areas inaccessible by road such as the Aleutian Islands or southeast Alaska. A mobile facility (Figure 12.7) should consist of a trailer (10 ft wide, 33 ft long) that is divided into three functional sections. The largest section is for triage and can hold up to eight otters in portable cages until they can be flown to the regional center. Otters arriving from the capture boats are examined by a veterinarian or animal care specialist and treated for hypothermia, dehydration, malnourishment, capture stress, or other medical problems. After they are medically stabilized, the otters are placed in critical care cages (Chapter 7, Figure 7.1) and monitored. The cages are placed in a shallow, fiberglass floor sink that collects waste water and drains into the sewer or a storage tank. A hose can be used to rinse the cages and the floor sink. Because heavily oiled otters have lost their ability to thermoregulate at cold temperatures, the room should be maintained at about 15°C (60°F). However, the otters should also be checked regularly to ensure that they are not overheating.

The triage area includes space for clinical blood analysis, communication equipment, and a desk. Blood samples from newly arrived otters should be analyzed for metabolites, electrolytes, and hematological variables. This information is vital for veterinarians to diagnose and treat immediate medical problems (see Chapter 4). This area is also used to store clinical supplies and drugs. Hot water is provided by a wall-mounted, propane-fueled instantaneous water heater. Communication equipment should include of a VHF radio and telephone (cellular telephones are very useful in areas with service). Good communication between the mobile facility and capture boats, helicopter, and the regional rehabilitation facility is vital. Administrative and animal health records are also kept in this area.

The other end of the trailer is used for sea otter food preparation. This kitchen is a smaller version of the one at the regional facility, consisting of a stainless steel counter for food preparation, a deep sink with fresh water for thawing frozen seafood, and a chest freezer (25 ft3). This is enough freezer space to store one week of food for ten adult sea otters.

The trailer should be designed with external connections for water, electricity, propane, and sewage. If these amenities are not available at the site, then backup systems are required. These consist of fifty-gallon portable storage tanks for fresh water and a 5kW diesel-electric generator with a fifty-gallon fuel tank. The generator should be housed separately in a noise-insulated, weatherproof container. In remote areas where sewage treatment is unavailable, waste water from the kitchen and sea otter holding area can be drained onto the ground by running a hose several hundred feet from the trailer. The waste water should contain only nontoxic, biodegradable substances such as food and feces. Portable propane tanks should be used for the instantaneous hot water heaters and space heaters. Additional outdoor space for holding sea otters in cages, storing equipment, and for conducting other activities that require shelter can be provided by portable, vinyl enclosures similar to those made by Weatherport Company (Anchorage, Alaska).

If the mobile unit is placed in a remote area without access to hotels and restaurants, then a second trailer will be required to provide living accommodations for the staff and a kitchen for their food preparation. If the trailer is placed on the deck of a large ship (i.e. an oil tanker), then fresh water, electricity, and waste water treatment, staff accommodations and meals can be provided on-board. The ship can move with the spill, and oiled sea otters can be transported to the shore-based rehabilitation center by helicopter.